- Hot-stamping effect

Hot-stamping is a method of finishings known for many years and the possibilities of choosing the right foil for hot-stamping are quite large. However, in many cases, a metallized paperboard will be a better solution. In this way, we will cut down the use of the machinery park in the printing house, and thus, we will reduce the time of order completion. In this way we can reduce the costs of packaging production. Lamination takes place before printing, so the effect of metallic motifs is obtained immediately after receiving the printed sheets. Thus, we will obtain an effect similar to hot- stamping. This is a completely different solution but it is worth remembering about this possibility when designing. Below we present an example of a packaging design in which almost all of the metallized raw material has been covered with opaque white as a base, and then all triad colors (CMYK). The elements of uncovered raw material imitate hot-stamping. Additionally, the design uses embossing in places where the raw material has remained metallic. The design has been completed with a UV matt varnish and a drip-off effect. This solution perfectly emphasizes the contrast between the finishings and makes the packaging more attractive.

- A small change, a spectacular result

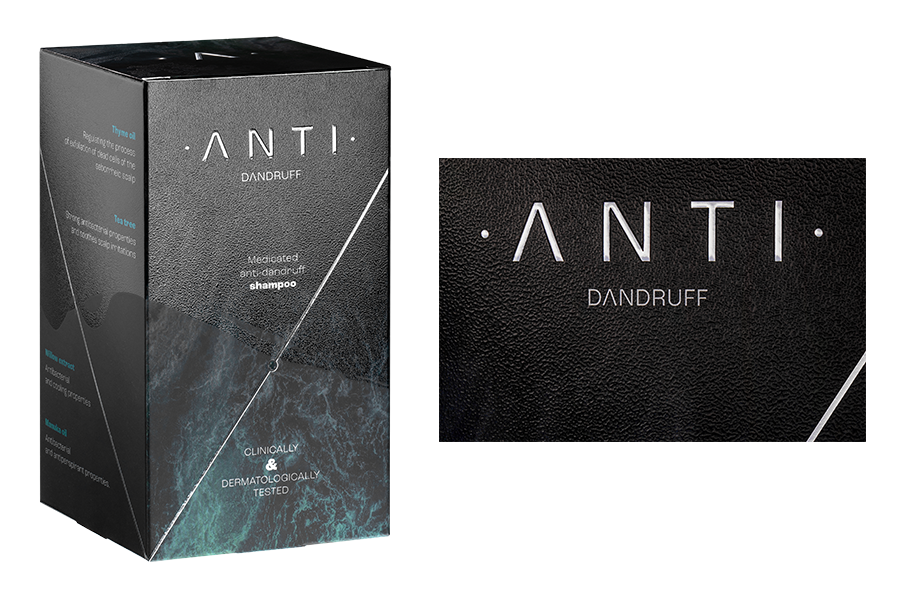

At first glance, the following example does not differ from the one described earlier, but the difference can be noticed by moving the packaging. Namely, in this solution, no backing white was used on the front and the back of the box. The second change is the game of varnishes. Thanks to this, we obtained the effect of shimmering waves, which means that the packaging will definitely attract the attention of buyers. The contrast between the surface with the base white and the printer’s ink applied directly to the metallized raw material is clearly noticeable and creates additional depth in the packaging. However, it should be remembered that the graphic design and technological preparation in the printing house play an important role here. The design uses embossing and the drip-off effect in the same way. This is an example that a small change in the production technology allows you to get really interesting visual effects. It is worth noting that only the metallized raw material allows you to create such contrasts when using triad paints.

- Finish with glossy UV varnish

In this project, the packaging was finished with a hybrid effect, and the whole was covered with a glossy UV varnish in order to obtain a high gloss effect. Similar to the package described above, the undercoat was not completely applied. The design also uses embossed elements in places where the metallized paperboard has not been covered with paints. The same project and the end result is completely different than before.

As you can see, printing on metallized cardboard allows you to get not only effective color impressions. This solution can be used to create an alternative to hot-stamping. A completely different result can be obtained by using double opaque white in printing, and the colors look different if we omit it in printing technology. The solutions used depend on the visual impressions we want to achieve. It should be remembered that high-quality effects in the premium packaging segment require a good graphic design that will emphasize the qualities of the laminate and finishings. Then, you should choose a professional printing house, the experience and machinery of which will allow you to obtain the visual effects assumed by the client.

It should be remembered that it is good to involve both your design studio and the selected printing house in the process of preparing the packaging. Conversation, exchange of ideas and real assessment in terms of the feasibility of the project is the best beginning of cooperation. Such communication is advisable already at the stage of graphic design, so that it is properly prepared for printing and cost-optimized.

This is how we work with clients at Preston Packaging to provide them with the highest level of service and support at every stage of implementation. Remember that packaging influences customers’ purchasing decisions. Thanks to solutions with a high standard of finishings, we will take care of the right effect, strengthening the image of your brand.