Quality is the most important

“Top quality” – a slogan we can find on almost every website. But does it still differentiate an offer today? Would any of us choose a low-quality product? Of course not. High quality should be the foundation of every company’s offer today to avoid the “it will somehow work out” situation. However, the word “quality” encompasses a whole range of actions and processes that not every company provides. And it must be understood that a low price never goes hand in hand with top quality. We’re not just talking about the quality of the product itself (although that can vary), but also about the level of customer service, communication methods and the automations used by the company to maintain the highest level of control.

When choosing a packaging printing company, it’s worth considering several aspects. The philosophy of cooperation and the inclusion of environmental aspects in the company’s activities, alongside price, timeliness of order fulfillment, and good information flow, have become the most important factors that influence clients’ choice of a printing company.

Unfortunately, a low price carries the risk of lower quality, which in turn can result in significant losses in many areas.

Complaints

The costs of complaints are one of the most obvious risks of choosing a “cheap printing house.” We must be aware that a low price doesn’t come from nowhere. This can mean a lack of adequate control over production processes, the use of materials from unverified suppliers, or an outdated production system that impacts the quality of the product.

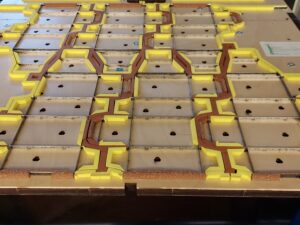

The biggest challenges for printing houses focus on producing the highest quality prints and applying attractive and often unusual enhancements. A printing house must have the resources and tools to control every stage of packaging production to deliver a solution that satisfies the client. It also needs to be able to check and advise the client if it sees any risks associated with the execution of the provided graphic design.

On one hand, complaints can result from inadequate process control. On the other hand, they can be due to the printing houses’s own sluggishness. It’s cheap, so “it is what it is.” The client provided the project, and the printing company executed it without considering technological limitations or potential technical problems that might arise in the client’s facility. If something doesn’t work on the packaging machines, it’s no longer the printing houses’s problem. The argument is simple: “the client wanted it this way, so we did it as requested.” This is what happens when choosing a cheap supplier. If you work with a printing house that cares about client satisfaction, you should receive technical support from the early stages of cooperation, which helps optimize the project for cost and avoid many production issues.

The complaint process incurs costs in the form of time spent preparing the necessary documentation, waiting for a response, and often strict deadlines.

And what if the printing house doesn’t accept our complaint? Will we release a “poor quality” package to the market? Do we have the resources to invest in another production run with a different supplier, and most importantly, do we have the time for this? For pharmaceutical companies, which must audit a new supplier before starting cooperation, flexibility in a crisis is also significantly limited. Companies in some industries might be willing to tolerate some quality issues and the form of cooperation. However, in the pharmaceutical sector, this is unacceptable. Pharmaceutical manufacturers often conduct a control audit in the printing house after a complaint. This generates further losses for them, as such audits also entail costs in terms of time and human resources dedicated to conducting it.

Therefore, it’s worth considering what is more important to us. A low price, which may hide unspecified risks, or the guarantee of good cooperation and the ability to focus on our own tasks.

Cost of downtime

Downtime in a company is an issue often overlooked in the context of choosing cheap packaging. However, problems associated with the late delivery of packaging can lead to significant disruptions in the production process. This results in halting the production line or delays in the packaging process. Consequently, it leads to reduced efficiency and increased costs related to the loss of productivity and profits. These downtimes are not only troublesome for production itself but also generate additional costs for the entire company.

The consequences of production downtime also affect the organizational atmosphere. Stress related to missed deadlines and the pressure to quickly find solutions can lead to a tense atmosphere within the company. This, in turn, can negatively impact employee motivation and the quality of their work. Can you really afford that?

Therefore, instead of focusing solely on the unit cost of packaging, it’s worth considering the potential costs of production downtime and loss of efficiency. One must look at the entire process, not just from the perspective of the Purchasing Department’s KPIs. When making purchasing decisions, it’s essential to consider the continuity of the process throughout the organization. Purchasing more expensive but specification-compliant packaging may seem like an overpaid investment. However, considering the entire process and the potential losses resulting from poor quality, it will certainly be a worthwhile investment. It will ensure the smooth running of the production process and eliminate additional costs.

Costs of product launch delays

Complaints often lead to another hidden cost not visible in the offer. Your product may not be available on time at the point of sale. Cooperation with large retail chains is regulated contractually, where late deliveries incur penalties. A delay in the product’s readiness for sale means a loss of potential profit during that period. Unreliable deliveries can cause customer dissatisfaction, threatening your reputation and potentially leading to a loss of brand loyalty.

Product damage and negative image

The primary function of packaging is to protect products. Low-quality packaging can be less durable and more prone to damage during transport. Product damage leads to financial losses and a loss of customer trust in the brand. Consequently, this can lead to complaints, restarting the cost spiral. However, this situation carries additional risks. In the age of social media and the omnipresent Internet, negative opinions about product quality can quickly spread online. A wave of negative comments can significantly harm the company’s reputation. Therefore, maintaining high-quality packaging becomes not only a financial issue but also a strategic one for maintaining a positive brand image.

An additional aspect of this situation is the cost associated with increased marketing efforts. When a product reaches the customer in poor condition, it not only creates a negative customer experience but may also require extra efforts from the company to repair its brand image.

Cost of losing brand trust

Product packaging serves not only a protective and practical function but also holds significant marketing importance. It’s often said to be the silent ambassador of your brand. Well-designed and well-made packaging attracts attention and can encourage purchase. Packaging is often the first point of contact a customer has with a product and can greatly influence brand perception. Its low quality can suggest a lack of care for the product or its low value, leading to a loss of brand image and customer trust. Poor quality packaging negatively impacts brand reputation and customer loyalty.

However, we often wonder whether it’s worth investing in more expensive packaging or if cheap solutions will suffice. It depends on the image you want to maintain and the experiences you want to provide your customers when they interact with your product. Often, a printing house can help you find the right solution that is both attractive and budget-friendly. The knowledge and experience of technologists, graphic designers, competent customer service, and modern software are often invaluable in collaboration. If you choose a partner who also cares about your success, you will have a team of experts from various fields at your disposal. They will ensure that your project is executed efficiently and professionally.

Consider whether you can rely on support and advice from your packaging supplier. Therefore, it’s worth considering this aspect of the collaboration the next time you compare two price offers.

What contributes to the cost of packaging besides raw materials and tools, and why is it sometimes more expensive than the competition?

In times when different printing houses have similar machines, use almost the same raw materials and deliver products of similar quality, what factors can influence price differences? Existing price differences can often be related to the cost of tools. Sometimes we reject offers because they seem overpriced in terms of tool costs. It’s worth considering the reasons behind this. Often, it results from choosing higher quality tools which, although initially costly, ensure durability and efficiency in the long term. This optimization can be beneficial as solid tools will last longer. Think about situations where it was necessary to repeatedly replenish the toolset in the printing house due to wear and tear. Then consider whether the initial choice of cheaper tools ended up being costly.

The packaging production process is very complex and involves many people. Besides raw materials, other materials necessary for executing individual orders, tool costs, machine operation, and labor, there are a number of other factors that shape the unit cost of packaging. Competitive advantage comes from management systems and the philosophy of collaboration, which are playing an increasingly important role in a company’s development.

Knowledge, professionalism, consulting, and well-organized processes are key to ensuring high-quality packaging. This seems obvious, but going back to the beginning of our article, low prices can “overshadow” the importance of these aspects. Choosing a printing house whose team checks whether the project is technologically feasible and may propose a more cost-effective solution to achieve the same effect is beneficial.

Have you ever been in a situation where you were looking for a printing house only after completing the packaging design? Have you chosen a provider and then found out that the production cost significantly exceeds the budget? This scenario repeats more often than one might expect. Designers create creative packaging concepts that are not always aligned with real production capabilities or require the use of expensive materials and processes. Unfortunately, it also happens that the graphic designers responsible for these projects do not have enough knowledge to balance aesthetics with economy.

So how do you reconcile high aesthetic demands with budgetary and technological constraints? The key is close cooperation with the printing house from the early stages of design. This partnership makes it possible to create a solution that is visually appealing and fits the production budget. Active involvement of the printing house from the beginning of the design process allows leveraging the knowledge and experience of specialists, translating into real production possibilities. Printing houses that know various technologies and available raw materials can proactively suggest modifications that maintain the project’s aesthetics while reducing production costs. A dialogue between the designer, brand owner, and the printing house helps eliminate potential problems at the design stage, significantly reducing the risk of costly mistakes during implementation. Therefore, choosing a partner who not only delivers packaging but also offers support and professional advice at every stage of implementation is crucial.

However, this is not the end of the factors that can add value to your collaboration. If your printing house evolves, introduces process improvements and systems that enhance communication and shorten order completion times, it is also a value to you and a time saver. Your team can calmly carry out its current tasks.

Summary

The role of high-quality packaging cannot be overstated. In addition to providing product protection, good packaging impacts brand image by attracting customer attention and standing out in the market. Therefore, investing in robust solutions can yield long-term benefits, even if they initially seem more expensive. A professional approach to customer service, automation of production and service processes, technological preparation, and advice on material selection or finishes can significantly enhance the quality of services provided, which affects the final price of the packaging.

It is crucial to choose a partner for cooperation who can provide all these elements. None of us would want to constantly worry about our orders. Choosing the right printing house will give you peace of mind, no questions from your superiors about delivery times, and business success.

Ultimately, even minimal differences in price (especially with large orders) may prove insignificant compared to the losses resulting from low-quality products and negative impacts on brand image. Therefore, before rejecting a higher offer again, ask yourself whether your company can afford to opt for the cheaper option?